BLOG

Choosing the Right Yellow Dye: Direct Yellow 11 vs 12 vs 86

Introduction

Yellow has always been one of the most versatile and widely used shades in the textile and paper industries. Whether applied to cotton fabrics, viscose blends, or packaging paper, the right shade of yellow can significantly affect the look, durability, and commercial value of the final product.

Within Direct Dyes, three products stand out as the most frequently used yellow dyes: Direct Yellow 11, Direct Yellow 12 (Chrysophenine GX), and Direct Yellow 86. At first glance, they may seem similar—all are azo direct dyes, all dissolve in water, and all are widely available. In reality, the differences in shade, fastness, and industrial applications are crucial, and buyers often evaluate them carefully.

This article provides a professional comparison of Direct Yellow 11, 12, and 86, helping trading companies and end users make informed purchasing decisions.

The Role of Direct Yellow Dyes

Direct dyes are water-soluble colorants applied directly to cellulosic fibers without mordants. Their key advantages:

Easy application in cotton and viscose dyeing

Economical, suitable for bulk production

Broad shade range for textiles, paper, and leather

Yellow is a foundation shade in industrial coloring, used both alone and in mixtures (to create oranges, greens, and browns). This makes Direct Yellow dyes especially important in large-scale production.

Shade Comparison: Visual Differences

Direct Yellow 11 → reddish yellow, warm tone, creates fabrics/papers with deeper, richer hues.

Direct Yellow 12 (Chrysophenine GX) → golden yellow, bright and clean, especially valued in the paper industry.

Direct Yellow 86 → greenish yellow, sharp and fresh, highly attractive for textiles requiring brightness and durability.

Even slight shade variations affect perception: packaging paper dyed with Direct Yellow 12 looks clean and premium, while apparel dyed with Direct Yellow 86 looks modern and resilient.

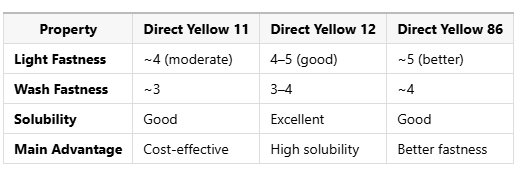

Technical Performance

Note: Actual performance depends on fiber, process, and auxiliaries used.

Best-Fit Applications

Direct Yellow 11

For cost-sensitive projects in cotton and paper

Popular in markets where moderate fastness is acceptable

Direct Yellow 12

First choice for the paper industry (tissue, packaging, printing paper)

High solubility → efficient for continuous paper dyeing

Direct Yellow 86

Preferred in textiles (cotton, rayon, blends)

Better fastness → suitable for export garments and fabrics exposed to sunlight

Buyer Considerations in International Trade

Performance vs. Price → DY11 is most economical; DY86 offers higher performance

Industry Demand → Paper mills prefer DY12; textile mills prefer DY86

Regulations → All must comply with azo dye restrictions & heavy metal limits

Logistics → Buyers prefer suppliers offering all three grades in one shipment

Market Demand Trends

India → Strong demand for Direct Yellow 12 in packaging/printing paper

Africa → Steady demand for Direct Yellow 11 & 12 in paper; DY86 rising in textiles

South Asia → Direct Yellow 86 popular for export textiles (Bangladesh, Pakistan)

Compliance & Support

At Uniwin, all Direct Yellow dyes are:

APEO-free, compliant with EU restricted azo regulations

Heavy metals controlled within global requirements

Supplied with COA and SDS for every batch

Free samples (10–50 g) available upon request

Technical support includes color matching and application guidance, reducing buyer risk in scaling up orders.

Frequently Asked Questions (FAQ)

Q1: What is the difference between Direct Yellow 11 and 12?

Direct Yellow 11 gives a warmer reddish tone, while Direct Yellow 12 provides a golden, cleaner yellow—preferred for paper.

Q2: Which Direct Yellow dye is best for textiles?

Direct Yellow 86 is ideal for textiles, with better light and wash fastness compared to 11 or 12.

Q3: Is Direct Yellow 12 suitable for paper mills?

Yes, its high solubility and bright golden shade make it the top choice for packaging and tissue paper.

Q4: Do all three Direct Yellows comply with azo restrictions?

Yes, Uniwin supplies only azo-compliant, APEO-free products, with full COA and SDS.

Conclusion

Choosing between Direct Yellow 11, 12, and 86 is not about which dye is universally “better,” but about matching the dye to the right application:

Paper industry → Direct Yellow 12

Textile industry → Direct Yellow 86

Cost-sensitive projects → Direct Yellow 11

By understanding these differences, buyers can make smarter sourcing decisions and maximize product value.

CATEGORIES

BLOGS

- Rising Sulfuric Acid Prices in China: Strategies for Global Dye Manufacturers

- Choosing the Right Yellow Dye: Direct Yellow 11 vs 12 vs 86

- The Future of the Dye Industry: How Automated Dye Dispensing Systems Are Changing the Game

- Eco-Friendly Sulphur Dyes: The Future of Sustainable Textile Manufacturing

- Achieving Carbon Neutrality in the Textile Industry with Tianjin Uniwin’s Sustainable Dye Solutions

CONTACT US

Tel: 8613642040418

Email:info@tjuniwin.com

Add: Liutangzhuang , Zhongtang , Dagang, Binhai District, Tianjin, China